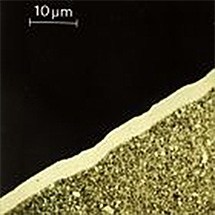

Gorilla coatings are just a few thousandths of a millimeter thick but harder than steel;

these low-friction coatings are extremely wear-resistant and chemically inert. The optimum coating is determined on the basis of both conditions of use and economic considerations.

GMX-35

Newly formulated, special high-performance coating for high speed machining. GMX-35 performance surpasses all conventional coatings. This universal high-performance coating is especially designed for milling and drilling. Also suitable for dry machining.

GMS2

Introducing a revolutionary, newly formulated, PVD coating process. GMS² marks a breakthrough in PVD deposition technology. The performance and hardness stem from the coating’s unique structure. GMS² is specifically designed to punish high temp alloys and is stock standard on the new Gorilla Mill Phenoms.

GDX-59

Introducing a revolutionary, newly formulated, PVD coating process. This process marks a breakthrough in PVD deposition technology. The performance and hardness of GDX-59 greatly Increases tool life in drilling applications.

| Coatings | TIAIN | ZrN | GMX-35 | GDX-59 | GMS2 |

|---|---|---|---|---|---|

| Structure | Multilayer | Monolayer | Gradient | Gradient | Gradient |

| Nanohardness (GPa) | 28 | 28 | 32 | 32 | 32 |

| Friction (fretting) Coefficient | 0.6 | 0.4 | 0.35 | 0.35 | 0.30 |

| Thickness (um) | 2-4 | 2-4 | 2-4 | 2-4 | 2-4 |

| Maximum Working Temp | 700°C (1290°F) | 550°C (1020°F) | 1100°C (2012°F) | 1100°C (2012°F) | 1100°C (2012°F) |

| Color | |||||

| Violet | Pale Yellow | Silver Gray | Silver Gray | Bright Gray |

Standard coating process temperature is 475° C (890° F)

Looking for the latest catalog?

View / Download It Today